Instrument tracking system for sterilization and surgery with RFID

Instrument tracking system for sterilization and surgery

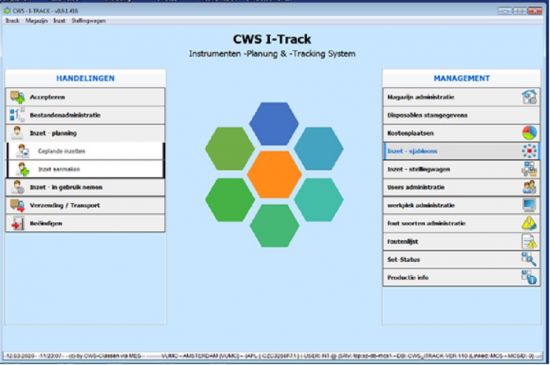

With our instrument management software packages MCS (for the CSA) and I-Track (for the OR) we offer in a few steps the possibility to find the right instruments and location.

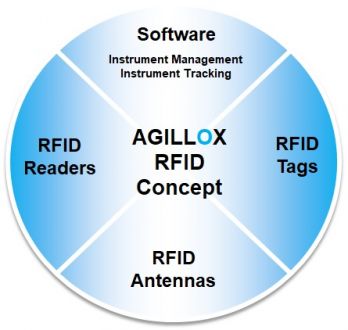

Thanks to the RFID chip, the entire process can be followed from the moment the instruments comes from the operating table until they are returned. Due to the modular construction, a personally desired working method can be set up

Reception of instruments in MCS

After use, the instruments are collected using the RFID system.

Because of this we are aware that the instruments need to be cleaned.

Instrumenst are registered and send to the next step in the process: Cleaning!

Cleaning

After intake, the instruments go to the washing machines. Thanks to the RFID chip in the nets and washing machines, the system is up to date. The system now knows that a certain net including instruments is in the washing machine, where it is being cleaned.

Compose instrument sets

The dedicated instruments per operation will be defined and composed for the next operation.

Sterilize

After the washing machine, the nets with instruments pass to the sterilizers. The instrument sets are sterilized after cleaning and covering.

This is also connected to the RFID system. When the nets are moved from the washing machine to the sterilizers, this is known to the system. The system records every step.

Supply cleaned sets

Finally, the sterile nets go to storage. This is scanned, after which it is known that the sterile net has returned to storage.

The benefit of the reader is that it is resistant to the cleaning resources.

I-Track for the purpose of OR and Policlinic

I-Track is used at the OR location in Amstelland hospital for the exchange of instrument sets to be cleaned with the Amsterdam UMC CSA department.

Thanks to the link between MCS on the CSA and I-Track at Amstelland OR, the cleaning of instrument sets between hospitals is performed in a transparent and efficient manner.

Full automatic control

the process is fully controlled and automated with the RFID system. Either mobile or fix readers will register the items in the different locations and send this to the host system. The data is stored so any history of items willbe stored and can be analysed at any time.

Doorways are used as gateways were the RFID system registers any movement when a trolley passes through. The different items which have tags mounted will be seen and the data is send to the server. Trolleys can be analyses as well any time with a mobile device at any place.

This gives the hosptial full transparency of usage, turn around time, maintenace cycles and location.